Aeronautical Engineering

Aeronautical Engineering Case Study

The Client

The Defence School of Aeronautical Engineering (DSAE) based at RAF Cosford, approached us to help with a particular engineering problem.

DSAE is the home for RAF Engineer Officer training and prides itself on being equipped with the latest training aids to support the learning of new Engineering Officers in the Royal Air Force.

The Proiect

As part of the Engineer Officer‘ s syllabus, they study the phenomenon of surge within an axial flow compressor. A specialist piece of equipment was designed and

manufactured in the 1950s to help illustrate this aeronautical anomaly, which can occur in jet engines under certain circumstances.

As part of the refurbishment of this equipment, a new compressor wheel was needed to be re-manufactured. Unfortunately, the company who supplied the training aid was no longer trading and no drawings of the equipment existed.

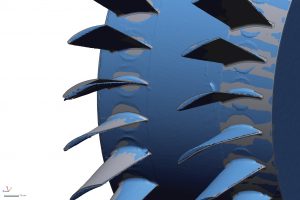

We used a laser arm to very accurately capture the geometry of the compressor vanes and hub.

The scan data was processed in Geomagic Design X to create a ‘Design Intent’ CAD model that would be used to CNC a new compressor.

During the design of the CAD model from the scan data, there were a number of vanes that were originally positioned incorrectly. It was only through the design process that these errors became apparent.

The image below shows that the vane scan data (in blue) does not match the equally spaced positions of the design intent CAD model (in grey).

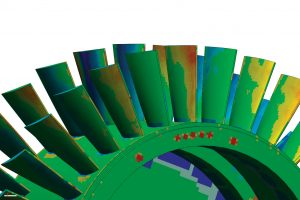

The image below shows the inconsistencies in manufacture of the original part when compared to the newly created CAD model.

Deviation set +/- 0.1 mm – (Green colour)

Summary

Combining our expertise to operate a high end laser arm scanner and Geomagic Design X software, meant that the project had within two days of modelling created a highly accurate and optimised CAD model directly from scan data. With the design of the compressor now being re-created, the Defence School of Aeronautical Engineering can continue to provide its students with a world class engineering education.

PDF Version

To download a PDF version of this page, please click here.