Civil Engineering

Civil Engineering Case Study

The Client

Connect Plus, a consortium of Skanska, Balfour Beatty, Atkins and Egis, manage the main arterial routes around London. During a routine inspection of the Boston Manor Viaduct, hair line cracks were discovered in some of the welds. 270 weld joints were inspected and of those, 41 needed custom plate repairs.

This initiated the Highways Agency to place a 7.5 tonne weight limit on the viaduct, which supports a section of the M4 motorway. With only 8 weeks until the Olympic Games opening, the viaduct needed to be fixed. Through the use of innovative SD technologies and close collaboration amongst dispersed and disparate teams, over 164 unique steel plates were designed, manufactured and installed, to provide a successful project outcome.

The Project

We were selected by main contractor Osborne to provide 3D laser survey and CAD model data for the project.

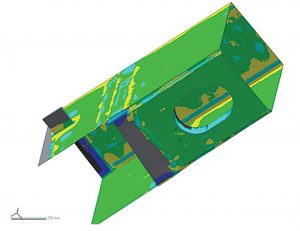

We converted the scan data to CAD models, and taking drawing information from ARUB the bridge engineers, created 30 computer models. These models were used to program robot controlled milling machines to produce the custom plates. Using a portable laser arm, our scanning team mobilised the laser scanner to be in close proximity to all flanges requiring dimensional characterisation.

Using this equipment meant a very fast, highly accurate, non-contact recording of the flange’s geometry was made. It also meant the number of operatives used and their exposure time in a hazardous environment was reduced considerably, compared to traditional measuring techniques.

With a highly detailed 30 surface scan quickly completed, our on-site team would process the data in site offices. The processed data was instantly uploaded using 36 mobile data services, onto a secure web portal to be analysed by ARUP based out of Solihull, West Midlands. They would perform structural analysis calculations to make informed decisions on whether a particular location required a custom milled plate or not.

Using our web portal in this manner meant decisions could be made in hours, not days. It also meant specialist teams were not required to be on-site, thereby alleviating the limited on-site resources available to essential personnel only.

“The CNC machine shops were working 24 hours a day, 7 days a week producing the custom milled plates”

It was critical that in order to hit the project deadline, the flow of good quality data from on-site through to the finalised designs was not interrupted through poor communication.

On average it took 12 hours to produce a set of plates. Using 30 models created from scan data meant dimensional errors were eliminated completely. Thereby saving the project time and additional cost in any plate re-manufacture that would have occurred using traditional measurement methods.

Summary

After 8 weeks of high intensity work, the repair was complete. Using the latest 30 laser technologies and high precision mechanical engineering solutions, the Boston Manor viaduct was able to fulfil its role in the Olympic Road Network.

PDF Version

To download a PDF version of this page, please click here.