X-Ray Inspection for Additive Manufacturing

The Need for New Inspection Techniques

With the advent of the additive layer manufacturing (ALM) revolution, the process in which we validate our creations can be as complex as the structures them selves. Seemingly impossible shapes are making traditional inspection techniques inadequate or even useless. Fortunately with the rise of ALM, industrial x-ray inspection machines have also risen in popularity due to their unique advantages and these advantages are allowing the inspections of new complex designs to continue with ease.

See Inside of Your Prints

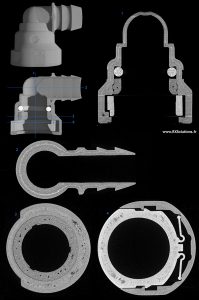

Traditionally the need to see within a part has been minimal due to the fact that conventional manufacturing techniques usually leave simple internal shapes or none at all. 3D printing has given designers the ability to create incredibly complex internal structures. These could be advanced cooling tubes in a heat exchanger or incredible geometric support structures. Either way, the quality of these are usually critical to the physical properties and structural integrity of the part.

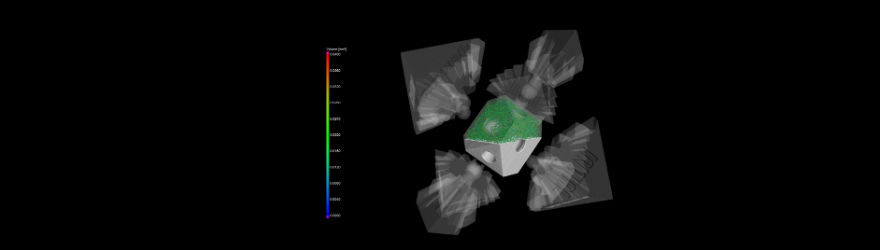

X-Ray machines allow you to get inside of your part and conduct detailed inspections. Until very recently the sample would have needed to have been taken apart if an assembly or cut open if a sole part. Either of these processes will induce certain artefacts to the inspection. How can you know exactly how a part interacts in an assembly when just looking at the separate, individual components and how can you quantify that a part has been made to tolerance if it is now in two or more pieces? The ability to virtually slice through a part or visualise the internal workings of an assembly with the individual parts in situ provide the inspector with far greater amounts of useful information.

For functional prints where structural properties are key it is also possible to visualise any porosities in the print. Any imperfection could mean a part can fail. All of these aspects can be quantified with industrial computed tomography.

The image below demonstrates one of the ways a component can be checked using X-Ray inspections.

Quality Inspections

Not only do x-ray inspection machines have the ability to inspect inside and out of samples, they also inspect to much higher tolerances than traditional inspection techniques. With resolutions up to 5μ (microns) the smallest of porosities can be quantified. As well as porosity checks x-ray inspection machines make it easy to check cracks and inclusions in the sample. Furthermore, it is fast and simple to make a comparison between the printed part and the CAD nominal, showing how the part is physically different from the design intent. These inspections tell you how your part will perform in the real world as well as give you a good indication if something is wrong with your printer allowing you to correct future problems sooner.

For more information on x-ray inspection machines contact us.

Download the Brochure

X-ray inspection for additive layer manufacturing brochure

Additive Manufacturing Brochure