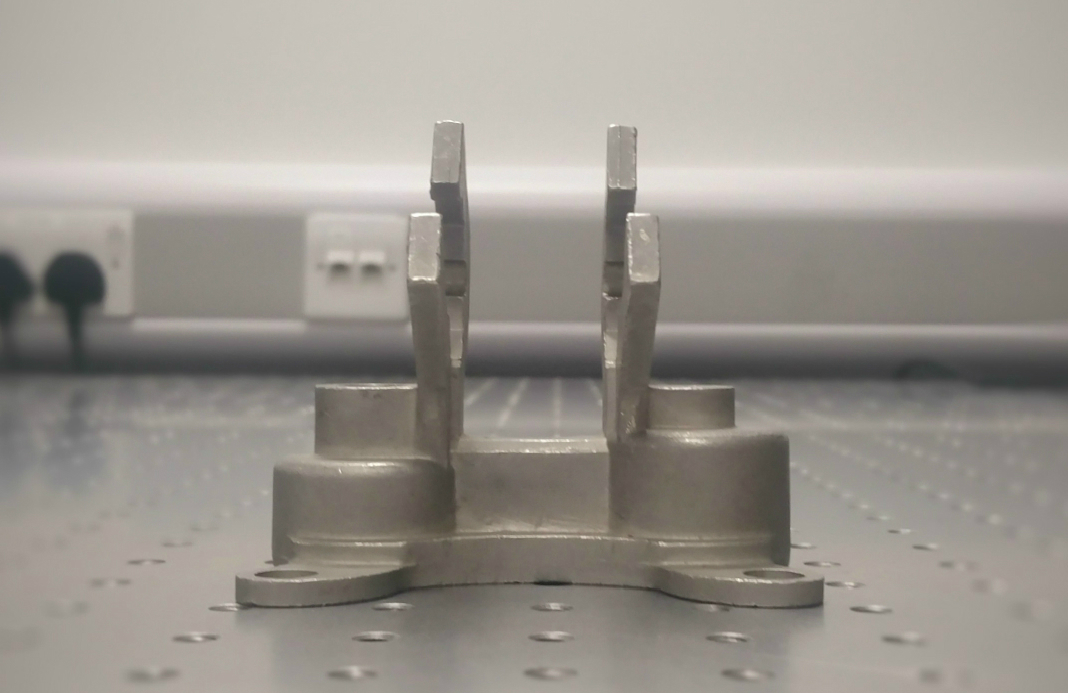

We use a range of 3D scanning technologies to capture millions of points that describe the geometric properties of the object. The raw scan data is referred to as a “Point Cloud” which can be used for taking dimensions. This data set can be used in inspection reports or as a guide for creating a CAD model.

Unless the project calls for the model to be created from the point cloud, the next step is to create a mesh model. This is done by connecting the points making triangular faces. Like the point cloud, the mesh can be used for inspection or taking dimensions. It is the mesh model that is normally used as a guide to create a CAD model. Features such as embossed text or even dents can be taken out of the mesh and basic geometry can be extracted to be used as a guide that speeds up the modelling process.

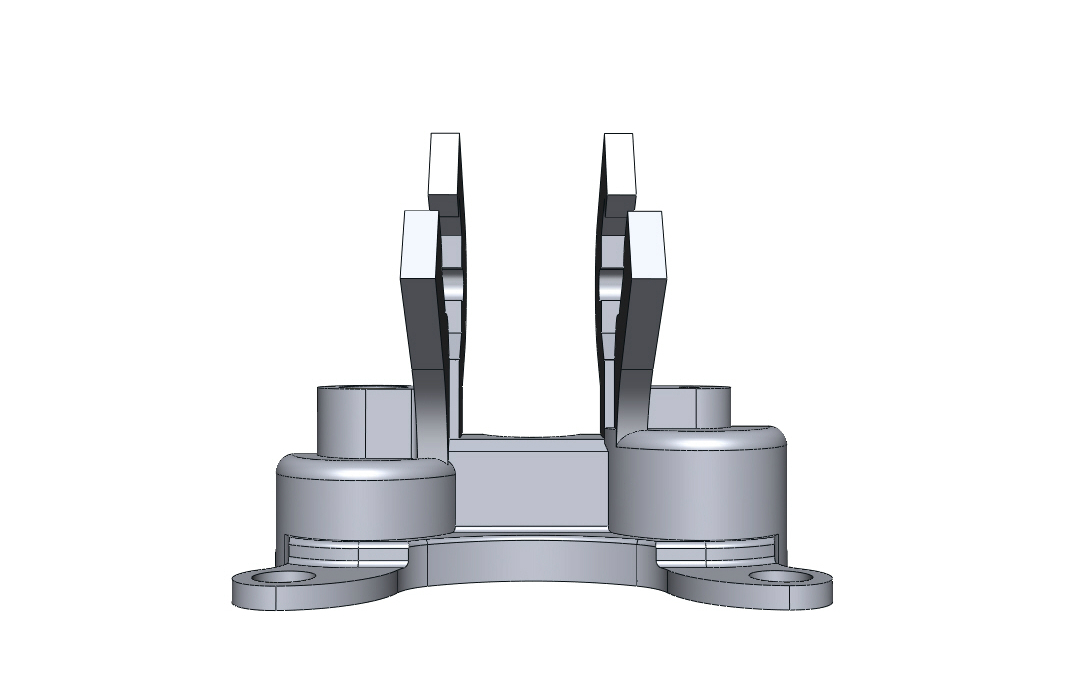

Using the mesh or point cloud as a guide, we create a CAD model which may be used in your existing CAD packages. The accuracy of the CAD model is checked against the initial scan data ensuring an accurate representation of the part.

Speak to us today on

+44 (0) 1691 777 774

3 Cedar Court, Brynkinalt Business Centre, Chirk, Wrexham, LL14 5NS

Find Us

“I first saw OR3D at a MAC event at the NEC, in Birmingham, when James was holding practical demonstrations. I realised how much easier it would be for us to have our products scanned and then rendered to make 3D models as, with clients across the world, sometimes language can be a barrier. We previously used photographs to advertise our products, but these 3D images are consistent, our products look uniform, and the overall effect is informative and professional. I would certainly recommend OR3D and look forward to using their services again.”

Simon Hanmer (Managing Director of Freddy Products)