Understanding RAAC and Why Inspection Matters

A guide to recognising, assessing and managing the risks of Reinforced Autoclaved Aerated Concrete

What is RAAC?

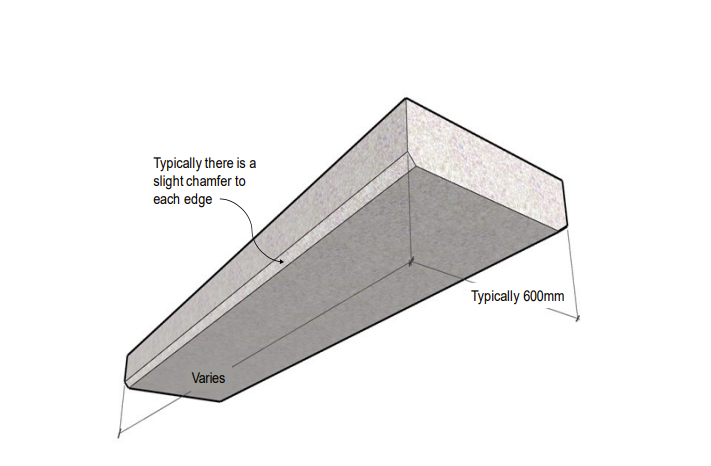

Reinforced Autoclaved Aerated Concrete (RAAC) is a precast, lightweight construction material that was commonly used from the mid-1950s through to the mid-1990s, particularly in public sector buildings like schools, hospitals, and offices.

Unlike traditional reinforced concrete, RAAC is highly aerated and much lighter. It was often favoured for its ease of installation and good thermal insulation properties.

You’ll most often find RAAC in:

• Roof planks (especially flat roofs)

• Wall panels

• Occasionally in floor slabs

However, it’s crucial to understand that RAAC is not a direct substitute for traditional reinforced concrete, as its mechanical behaviour and long-term durability are quite different.

Why is RAAC a Concern?

Although RAAC served a purpose during its time, its long-term performance has raised serious safety concerns.

Key issues include:

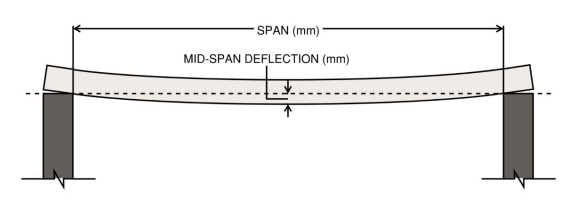

• Creep and deflection: Over time, RAAC panels can sag, especially under consistent load or where thinner panels were used.

• Water ingress: The porous structure of RAAC allows water to penetrate easily. This not only weakens the material but can corrode internal steel reinforcement.

• Hidden structural failure: In some cases, RAAC panels can collapse suddenly, particularly if:

o The internal steel stops short of the support point.

o There is insufficient bearing at panel ends.

o The reinforcement has corroded significantly.

These factors make early identification and regular inspection critical, especially in buildings where RAAC is suspected but hasn’t yet been confirmed.

Why Is It Difficult to Inspect?

RAAC panels are often found above suspended ceilings, inside service voids, or under roof membranes, making visual inspection difficult without partial removal or specialist equipment.

In many cases, organisations are unaware that RAAC is even present until symptoms appear – or a broader national review prompts action. That’s where professional RAAC inspections come in.

How OR3D GEO Can Help

At OR3D GEO, we deliver specialist RAAC inspections that minimise disruption while maximising data accuracy.

Our Approach

1. 3D Laser Scanning with the Trimble X12

We use high-precision terrestrial scanning to capture sub-millimetre resolution data, even in dark, enclosed, or hard-to-reach areas. The onboard lights and colour cameras enhance visibility of cracks, staining and surface changes.

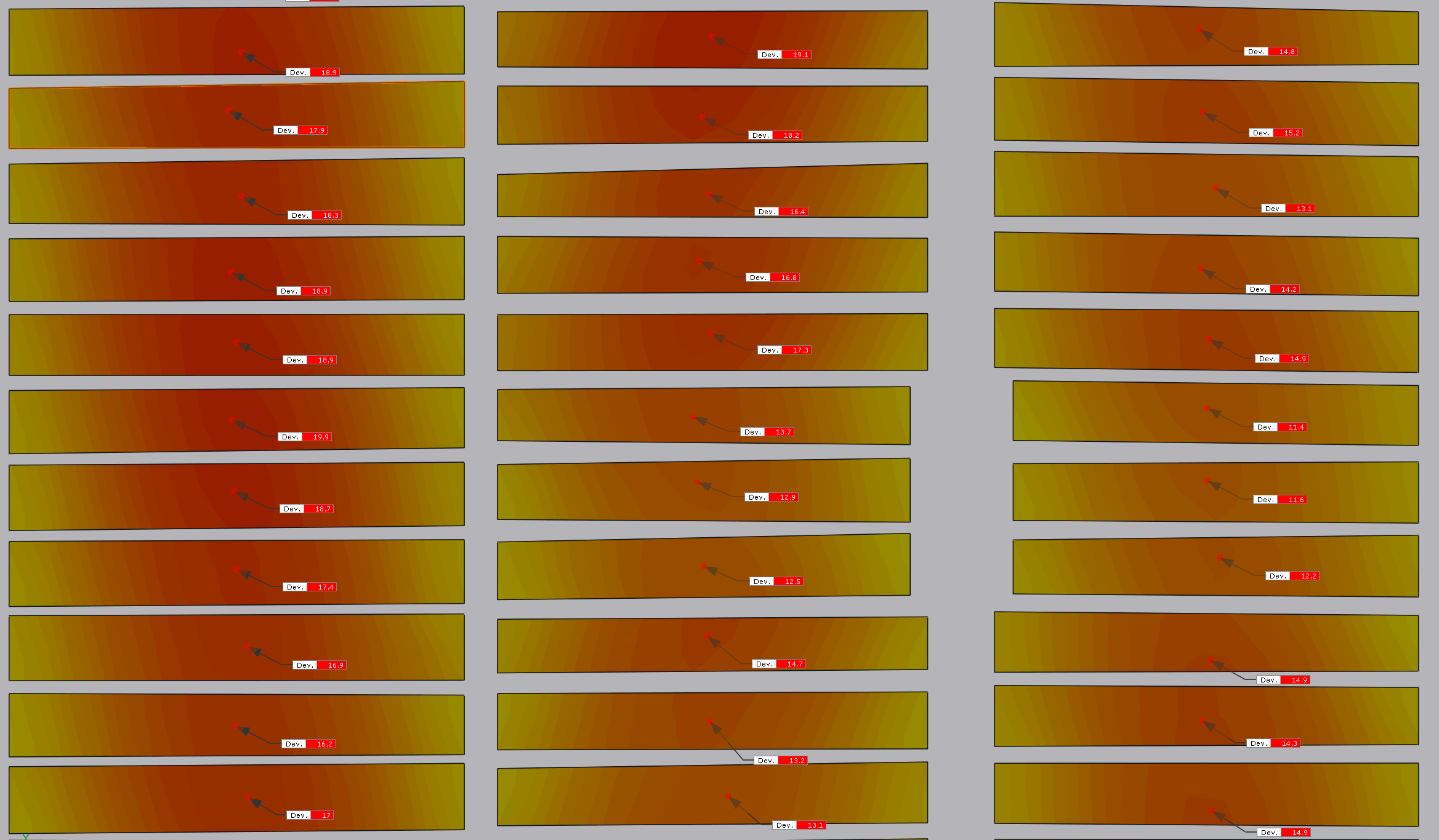

2. Digital Analysis with Geomagic Control X

Once data is captured, we process it in Geomagic Control X, where we can:

o Compare scans to CAD models

o Map surface deviations

o Detect mid-span deflection or panel warping

o Export heatmap-style colour models

3. User-Friendly Outputs

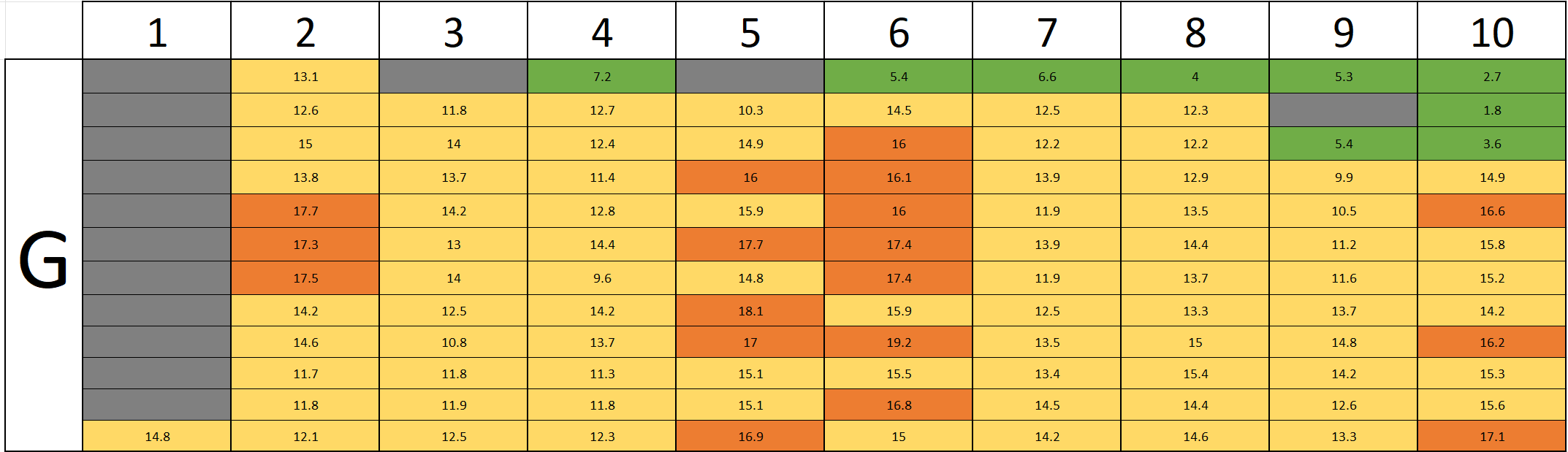

All findings are packaged into clear, accessible formats – PDF reports, annotated images and Excel spreadsheets – with no need for specialised software to view results.

Excel slab deflections