Knowledge Base

OR3D’s comprehensive Knowledge Base Blog, your go-to resource for all things related to 3D Printing, Scanning, CAD Modelling, Reverse Engineering, Robotics, and company announcements. Our knowledge base is designed to empower you with the latest industry insights and news.

Geomagic

OR3D receives Business Innovation award at Geomagic, EMEA Partner Summit

OR3D is delighted to receive the Business Innovation award from Oqton at the EMEA partner summit in Athens. The award honours the recent launch of OR3D’s Geomagic For SolidWorks online training cour...

15th March 2024

1 min read

OR3D launch new and online Geomagic For Solidworks course

5th February 2024

What a start to the year for OR3D.

1st February 2024

SIMON BAYNES MP EXPLORES TECHNOLOGICAL INNOVATION AT OR3D IN CHIRK

1st December 2023More articles

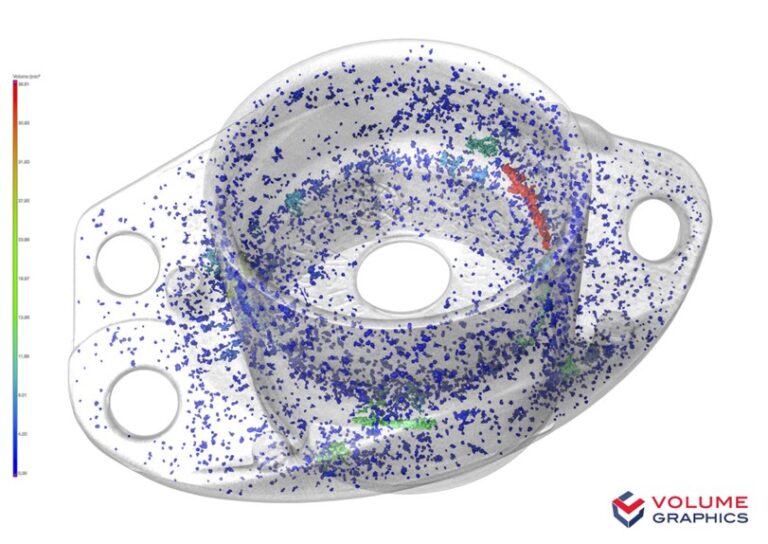

Control X

Control X

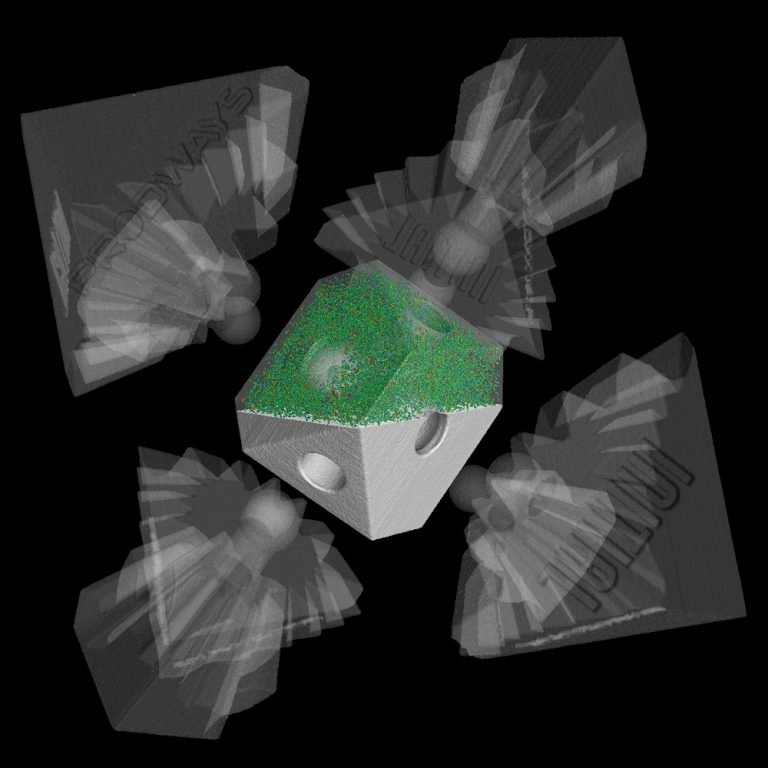

New updates coming soon for Geomagic Design X and Geomagic Control X

7th July 2023

1 min read