Oil and Gas

Oil and Gas Case Study

The Client

Dynamic Equipment Company (DEC) is a specialist engineering services company, working in the offshore and onshore oil industry. Based in Aberdeen, the company offers bespoke mechanical handling solutions, such as cranes and lifting equipment, to clients across the world.

Summary

DEC has long been at the forefront of technology in its industry. With a focus on accuracy, DEC first used solid modelling packages to replicate client installations, which gave a high degree of flexibility for developing new products and bespoke solutions.

However, with the company moving into 3D surveying to measure client’s offshore and onshore drilling installations, DEC was capturing more data than ever before.

While the scanning offered a high degree of accuracy, the process of translating that information into solid models was time consuming and expensive. Simply put, the 3D scanning equipment offered more data than could be easily processed using their current systems.

The Solution

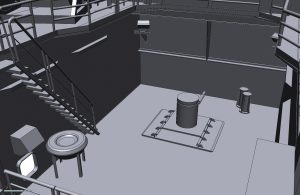

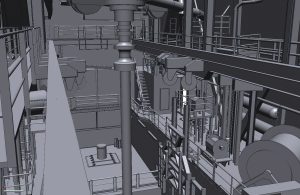

Using an orbital laser scanner, DEC’s experienced team continues to carry out the equipment site surveys but this information is now passed to us, where we use Geomagic Design X to create highly accurate, 3D CAD models.

These computer generated CAD models are more accurate, time efficient and effective than solid models, meaning that DEC’s engineering team can quickly get to work in designing a solution based on real world data.

Client Comments

Richard Hay, founding partner of DEC said:

“By scanning the work area, one person can make an accurate, detailed survey in a day. What’s more, that day will collect 1OO times more data than a team using traditional methods would be able to take in four days.

“Our problem was that having collected so much data, we needed to be able to translate it into accurate drawings and models, which is where James Earl’s team at OR3D come in. They translate the data into 3D CAD drawings, which we can share with our clients and engineers to use in the design and manufacture process.”

“When it comes to fitting the equipment, the high-tech, 3D process has significant cast, time and safety benefits,” Richard explained.

“Such is the accuracy of the scanning equipment, we can be confident that the new or upgraded equipment will fit without clashing first time, ” he said. “This makes the whole process safer and more efficient, saving us and our clients time and lost productivity.”

PDF Version

To view a PDF version of this page, please click here.