Exploring the Inner Workings of Vintage Radios with Digital Radiography

Digital Radiography

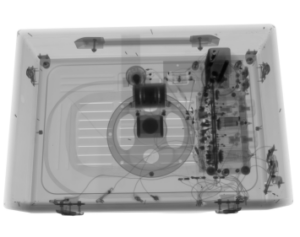

In an age where technology advances at lightning speed, there’s something truly special about taking a step back in time. Vintage radios, relics of a bygone era, hold a unique charm with their intricate designs and timeless appeal. Recently, we had the opportunity to delve into the inner workings of two such radios—one from the 1950s and another from the 1970s—using a service called Digital Radiography.

In an age where technology advances at lightning speed, there’s something truly special about taking a step back in time. Vintage radios, relics of a bygone era, hold a unique charm with their intricate designs and timeless appeal. Recently, we had the opportunity to delve into the inner workings of two such radios—one from the 1950s and another from the 1970s—using a service called Digital Radiography.

This blog will walk you through how digital radiography works, its advantages, and how it allowed us to inspect these vintage radios and various other items without causing any damage.

What is Digital Radiography?

Digital radiography is an advanced imaging technique that uses X-rays to create digital images of an object’s internal structure. Unlike traditional film-based radiography, where X-ray images are captured on physical-film, digital radiography uses digital detectors to produce high-resolution images that can provide live images that can be instantly viewed, analysed and stored.

This technique is invaluable across various industries, from medical imaging to industrial inspections. It’s particularly useful for non-destructive testing (NDT), where the goal is to examine the internal structure of an object without causing any damage.

Digital radiography offers several key advantages over conventional methods, including:

Higher Image Quality: Enhanced resolution and clarity provide better insights into the object’s internal structure.

Dynamic Imaging: The ability to capture and analyse moving objects or processes in real-time.

Faster Processing Time: Instant image generation allows for quicker analysis and decision-making.

Ease of Storage and Transmission: Digital images can be easily stored, shared and archived, making them more accessible.

A Journey Through Time

Our project involved two vintage radios – one from the 1950s and another from 1970s. These radios, with their unique designs and components, represent the evolution of radio technology over the decades. However, opening them up for inspection would risk damaging their delicate, aged components. This is where digital radiography came into play.

Using digital radiography, we scanned these radios to inspect their internal components without the need for disassembly. The X-ray images revealed the intricate wiring, coils, capacitors and other components that power the radios. This non-invasive technique allowed us to appreciate the craftmanship that went into these devices while preserving their historical integrity.

To get the most out of the digital radiography scans, we employed several image processing techniques. These enhancements improved the visibility and quality of the radiographic images, providing clearer insights into the radios’ internal structures:

- Contrast Enhancement: Adjusting the contrast levels helped us highlight specific features, making it easier to distinguish between different components.

- Noise Reduction: This technique minimised any unwanted artifacts or distortions in the images, resulting in cleaner and more accurate visuals.

- Edge Detection: By emphasising the edges of various components, we could better understand their shapes and configurations.

- Defect Segmentation: This allowed us to identify and isolate any potential defects or damages within the radios, such as cracks, corrosion, or broken parts.

The Limitations of Digital Radiography

While digital radiography offers numerous benefits, it’s important to acknowledge limitations. The primary limitation is that it only produces 2D images, which can make it challenging to measure the depth or size of any internal defects. For instance, if there was a crack inside one of the radios, we could see it on the X-ray image, but determining its exact depth, volume and position would be difficult.

To overcome this limitation, we recommend using Computed Tomography (CT) as a complementary technique. CT scanning provides a comprehensive 3D view of the object, allowing for more detailed analysis and accurate measurement of internal features. By combining digital radiography with CT, we can achieve a more complete understanding of an object’s internal structure.

For more information on our digital radiography services and how we can help you explore the hidden details within your valuable objects, visit OR3D CT.