Exploring the Capabilities of 4D CT

Tracking Dynamic Changes in a Stress Ball with Rx Solutions

Exploring the Capabilities of 4D CT

In the realm of technological innovation, 4D Computed Tomography (4D CT) holds a lot of potential for a wide range of applications. From industrial inspections to research and development, 4D CT is assisting organisations to visualise and understand complex processes in both temporal and spatial resolutions.

In this blog post, we’ll explore the applications of 4D CT; how it is transforming inspections for various industries, including a case study involving the monitoring of local density during the compression of a stress ball.

What is 4D CT?

4D CT, or Four-Dimensional Computed Tomography, is an advanced imaging technique that goes beyond traditional 3D CT by incorporating the element of time or space. It captures a series of 3D scans over a period, creating a dynamic sequence that reveals changes and movements within the scanned object. This extra dimension provides invaluable insights into the behaviour and functionality of the subject, making 4D CT a powerful tool for a multitude of applications.

Industrial Inspection: Enhancing Quality and Efficiency

One of the most promising uses of 4D CT is in the field of industrial inspection. Quality control and assurance are critical in manufacturing processes, and 4D CT offers unparalleled capabilities for non-destructive testing. Here’s how:

- Monitoring Structural Integrity

In industries such as aerospace, automotive, and healthcare, ensuring the structural integrity of components is paramount. 4D CT can be used to monitor the performance of materials under stress, observe how they respond over time, and detect any potential defects or weaknesses. This dynamic insight helps engineers design more robust assemblies and prevent failures.

- Analysing Mechanical Movements

For machinery and mechanical components, understanding the precise movements and interactions of parts is crucial for optimising performance and longevity. 4D CT allows engineers to visualise these movements in detail, identify areas of wear and tear, and improve design for better efficiency and durability.

Demonstrating the Power of 4D CT: Tracking Dynamic Changes in a Stress Ball with Rx Solutions EasyTom 230

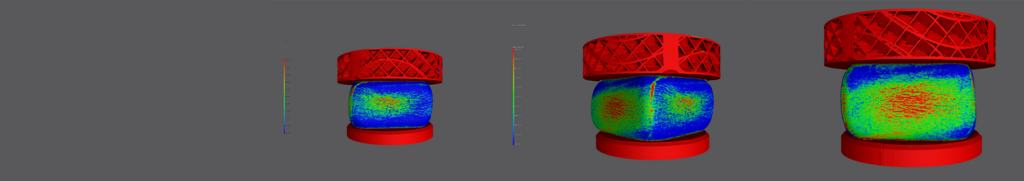

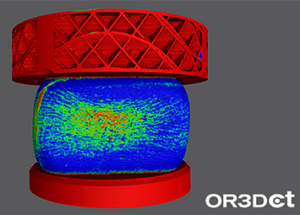

OR3D CT utilised 4D CT technology to track the local density of a stress ball, showcasing the dynamic changes it undergoes during compression. This experiment was conducted using our EasyTom 230 CT scanner from RX Solutions.

Multiple Sequences

The project involved capturing multiple CT scans of the stress ball under varying levels of compression. resulting in over 70 detailed tomography’s. These individual scans provided a comprehensive view of how the stress ball deforms and recovers, illustrating the intricate dynamics of its material properties. Thanks to our internal design team we were able to manufacture a load cell specifically designed for this application.

Automated Scanning

One of the key advantages of this project was the fully automated scanning process. From the initial acquisition of images to the final reconstruction, the entire workflow was seamlessly managed by the EasyTom 230 system . The system which is well known in the academic industry for insitu experimentation allowed the OR3D team to automate both the CT scan acquisition and the adjustment of the in house designed load cell which enabled us to run the study overnight. The automation not only enhanced efficiency but also ensured a high level of precision and consistency in the results.

Versatility of 4D CT

The use of 4D CT in this project highlights its versatility and capability to monitor and analyse dynamic changes over time. By observing the stress ball’s compression and relaxation cycles, we demonstrated how 4D CT can provide detailed insights into material behaviour. This level of analysis is crucial for industries that require precise monitoring of mechanical properties and material integrity.

Precision and Efficiency

The precision and efficiency of the 4D CT scanning process is evident in the detailed reconstructions obtained from the stress ball sequences. The ability to capture fine details of the internal structure and the changes it undergoes during compression showcases the potential of 4D CT for various applications. Whether it’s for quality control in manufacturing, material science research, or other industrial applications, 4D CT offers unparalleled potential for new and exciting 3D data analysis .

For more information on the abilities of 4D CT visit https://www.or3d.co.uk/the-ct-centre/4d-ct/ or contact the CT team on 01691 777 774.