X-Ray Inspection and NDT

Why NDT? Non-Destructive Testing allows for the inspection, analysis and investigation of a sample without the need to break the sample open or damage it.

Using these techniques, made available by X-Ray inspection machines, we can run more types of inspections and tests, allowing for a more detailed and thorough analysis of parts. The sample can be used after the inspection process and the inspection wont contain any artefacts generated during the destruction of the sample.

NDT can be used through all phases of the products life cycle. R&D, Design, manufacture, quality control and in customer returns. Learn more about NDT and how it is used here.

Principals of X-Ray Imaging

X-Rays are part of the electromagnetic spectrum. With a short-wave length, they appear between the Ultra Violet and the Gamma regions of the spectrum. They are a penetrating radiation and interact with the matter that they encounter. Radiation energy can be measured in electron Volts (eV).

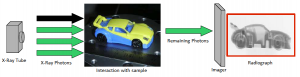

To produce an X-Ray image, transmission imaging is used. The process in principal is very simple. A single X-Ray image is known as a Radiograph and the process of acquiring it is known as Radiography. An X-Ray tube will produce X-Ray photons and propel them towards a sample. Due to the fact that X-Rays are a penetrating from of energy they will pass through the sample and on towards an imaging plate or detector. The imaging plate works in a similar way to a CCD in a camera. The X-Rays are blocked by differing amounts by the sample depending on the material type and thickness. Therefore, on a medical X-Ray you can see bone amongst the soft tissue.

Radiography

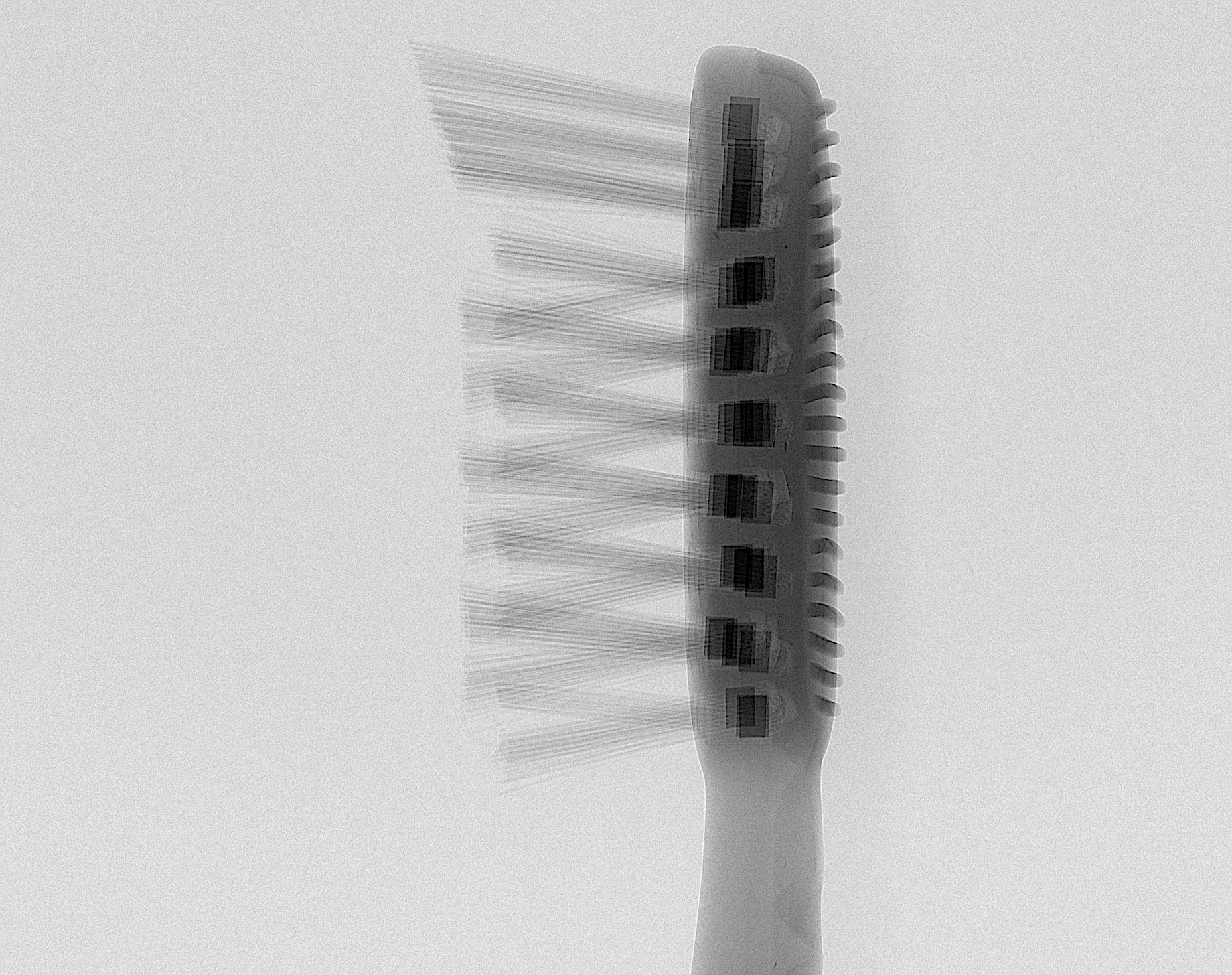

Radiography is a 2D image representing the X-Ray photons that passed through the sample. The interaction of the X-Rays and the sample depend on the photon energy (eV), the atomic number of the atoms in the sample and the density of the sample. X-Rays will pass through the sample easily if they have high energy, the sample is made up of light weight atoms, if the sample has a low density or if the sample is narrow perpendicular to the flow of photons.

The more photons that pass through the sample the more exposed the imager will become. An X-Ray system will then create a greyscale image based on the exposure of the individual pixels in the images. Typically, low exposure (high density) would be seen as a dark area in the image and high exposure, low density, would be seen as light. This is the same in medical X-Rays acquisitions although the results are inverted. Bone (high density) appears white.

Radiography has limitations. From a single radiograph, it is not possible to determine the depth of parts seen in the image within the sample. It can be difficult to interpret complex component structures and some components could be hidden by dense parts either in front or behind of them. The solution to this is Computed Tomography (CT) which is the virtual slicing of the sample.

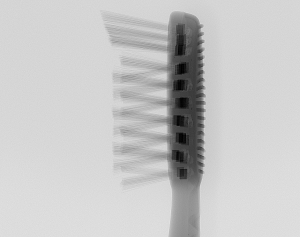

Radiograph of Tooth Brush Using DeskTom Scanner

Radiograph of Tooth Brush Using DeskTom Scanner

Computed Tomography

Computed Tomography is the 3D reconstruction of many individual radiographs. Either the imaging system or more commonly the sample is rotated (contrary to medical imaging). With several hundred radiographs of the sample from different angles, specialist software can be used to reconstruct a 3D volume based on many thin slices through the sample.

Using this technique, it is possible to analyse a part in three dimensions. The 3D position of parts within a sample can easily be analysed.

Reconstructed Slices from Computed Tomography

Download the Brochure

X-ray Computed Tomography brochure