Analysing the Evolution of Atari

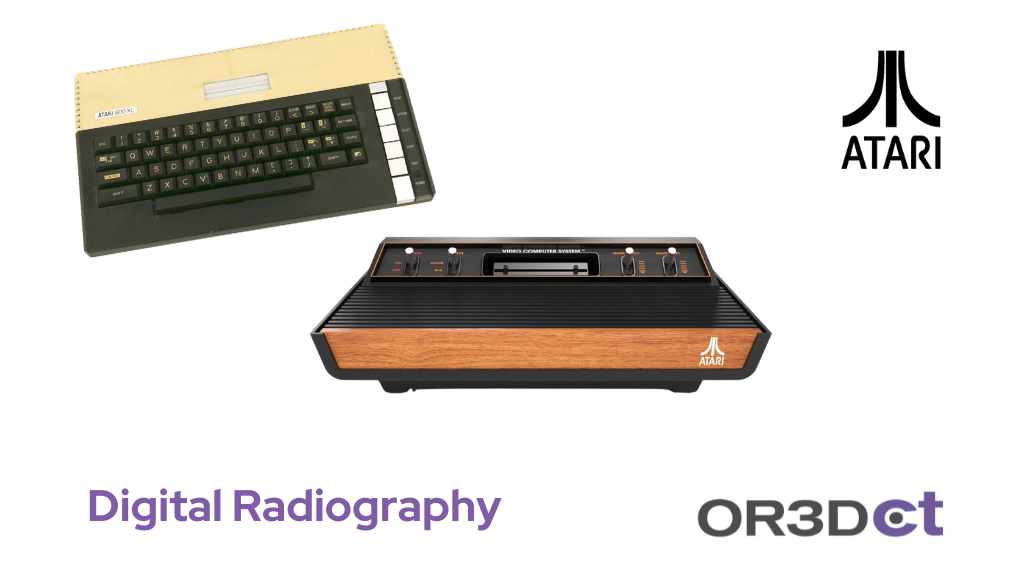

Atari 800XL vs. the Latest Atari 2600 in Digital Radiography

As gaming technology advances, it’s fascinating to look back at the inner workings of iconic gaming consoles. Today, we’re exploring the Atari 800XL from the early 80’s and the latest Atari 2600 using digital radiography (DR) imaging to reveal their electronic structures and understand how technology has transformed over the decades. Thanks to OR3D CT’s expertise and the advanced capabilities of the EasyTom 230 scanner, we were able to capture incredibly detailed X-ray images that highlight the contrast between early 1980s design and modern engineering.

The Radiography Process at OR3D CT with the EasyTom 230

To capture the intricate details inside these consoles, OR3D CT use the EasyTom 230, a high-powered industrial CT scanner from RX Solutions. OR3D CT captured high-resolution radiographic images to reveal the internal architecture of the Atari 800XL and the latest Atari 2600.

The EasyTom 230 scanner is known for its precision and versatility, designed to handle both small, complex objects and larger items like entire electronic devices. With its 230 kV X-ray source, the EasyTom 230 can capture fine structural details that are often difficult to see with standard imaging techniques. By rotating each console during the scan, OR3D CT captured a series of X-ray images from multiple angles, which were then processed to create clear, layered images of each console’s internal components.

The result is a set of incredibly detailed radiographs that allow us to study each console’s electronic layout without dismantling them, preserving the integrity of these classic machines. This process gives us a rare, non-invasive look into how Atari’s hardware design has evolved over the years.

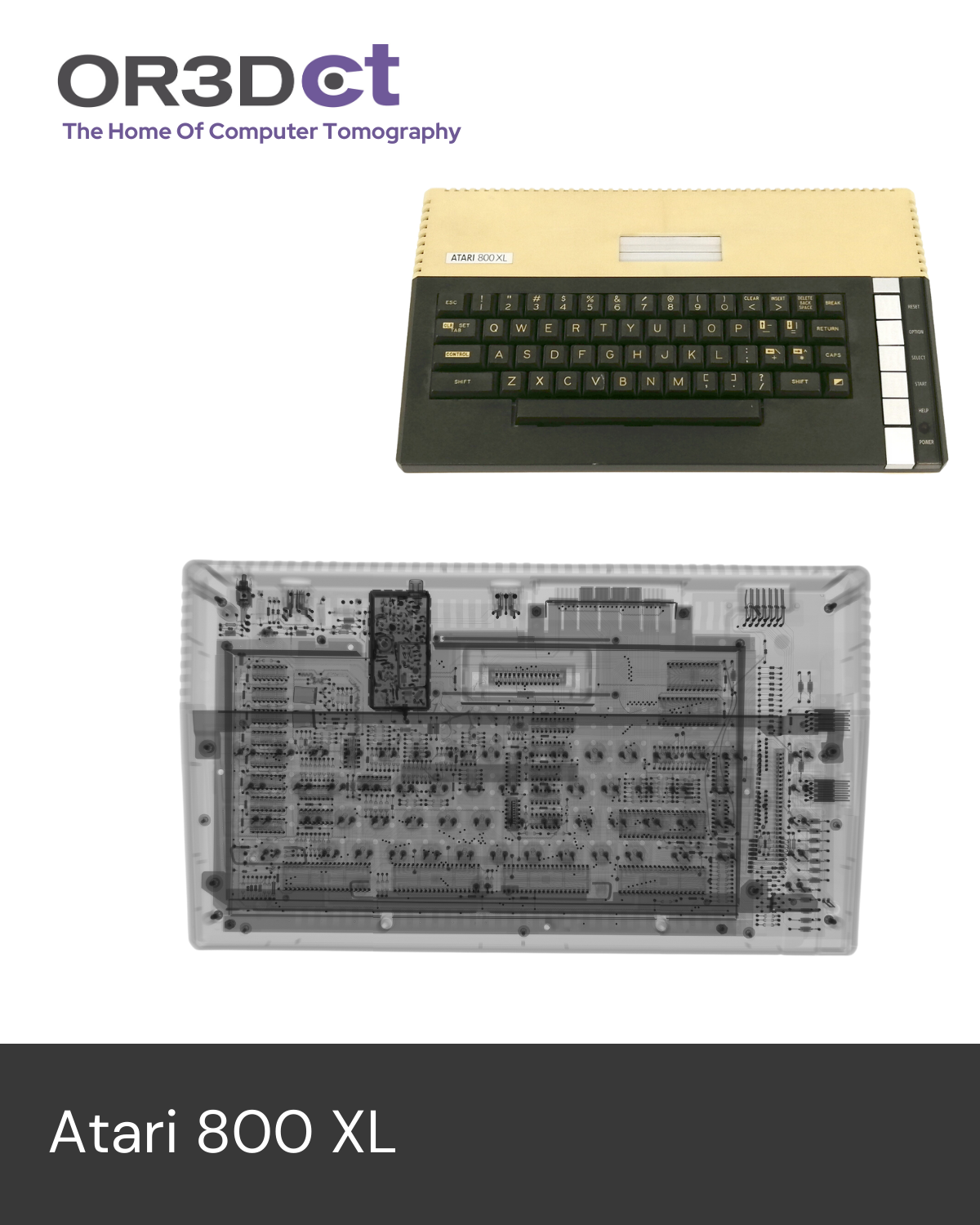

The Atari 800XL: Complex Circuitry and Early 8-Bit Computing

The Atari 800XL, released in 1983, was an 8-bit powerhouse of its time. The radiographic image of the 800XL showcases a densely packed circuit board with numerous visible components, including capacitors, resistors, and integrated circuits. The layout reflects the complexity of 1980s computing, when every function required dedicated circuitry, and each component took up significant physical space.

Notable features include:

- High Component Density: The circuitry is densely packed, with each chip and capacitor playing a specific role in executing basic graphics and processing functions. This reflects the limitations of the era’s technology – each function demanded its own dedicated hardware.

- Visible PCB Layers: You can observe the stacked layers of the PCB (printed circuit board), necessary to support complex pathways for processing and memory management.

- Discrete Components: Capacitors, resistors, and connectors are clearly visible, demonstrating how hardware was used to manage power distribution and signal processing.

Overall, the Atari 800XL’s internal structure looks intricate and layered, representing the era’s approach to electronics when hardware space was ample, but component miniaturisation was limited.

The Latest Atari 2600: Streamlined and Modernised for Efficiency

The latest Atari 2600, designed to reflect the look of the classic console while housing modern internals, showcases a very different internal structure. This new Atari leverages decades of advancements in electronics miniaturisation and efficiency. In the radiographic images captured with the EasyTom 230, we see a far simpler and more streamlined design, with fewer individual components and a larger reliance on integrated circuits (ICs).

Key observations include:

- Simplified Design with Fewer Components: Compared to the 800XL, the new 2600 has far fewer visible components. Integrated circuits are used to handle functions that would have required multiple discrete components in the past, reducing both size and power consumption.

- Greater Use of Surface-Mount Technology (SMT): Components are attached directly onto the surface of the PCB, a modern manufacturing method that minimises space and enhances durability.

- Centralised Mainboard: The 2600’s mainboard appears more centralised, with fewer layers and a straightforward layout. This simplified structure reflects advancements in circuit integration, where complex functions are now achieved with a single IC.

This streamlined layout reflects how gaming consoles have evolved to be more power-efficient and compact. The new 2600 is built with fewer materials and optimised for easier assembly, which would have been nearly impossible in the era of the 800XL.

Comparing the 800XL and Latest 2600: The Impact of Technological Advancements

Digital radiography with the EasyTom 230 highlights the contrast between the Atari 800XL’s complex, component-heavy design and the latest Atari 2600’s minimalist, streamlined approach. Here’s a side-by-side analysis:

| Feature | Atari 800XL (1983) | Latest Atari 2600 |

| Circuit Density | Dense, complex layout | Simplified, centralised mainboard |

| Component Type | Discrete components | Integrated circuits (ICs) |

| Manufacturing | Through-hole technology | Surface-mount technology (SMT) |

| PCB Layers | Multi-layered with visible trace complexity | Single or few layers, simplified |

| Design Philosophy | Function-specific components | Multi-function ICs for efficiency |

This comparison underlines the massive shift in hardware design philosophies over the past few decades. The Atari 800XL’s internal layout was built for a world where each electronic function required dedicated components. Meanwhile, the latest Atari 2600 embodies the streamlined, efficient approach of modern electronics, where single chips handle multiple functions.

Share Your Thoughts and Memories

Whether you grew up with the Atari 800XL or are just discovering the latest Atari 2600, we’d love to hear your thoughts! How do you feel about the evolution of Atari consoles? What are your favourite memories of playing on these iconic machines?

Explore More with OR3D CT

There’s much more to discover with OR3D CT. Our CT scanning services offer unparalleled insights into a wide range of materials and structures. We assist industries such as aerospace, automotive, electronics, medical devices, archaeology, and more, providing precise 3D imaging that helps with quality control, product development, and research. Whether for complex industrial applications, historical artifact preservation, medical device analysis, or just the joy of exploring the unseen, our team is dedicated to revealing the intricacies that lie beneath the surface.