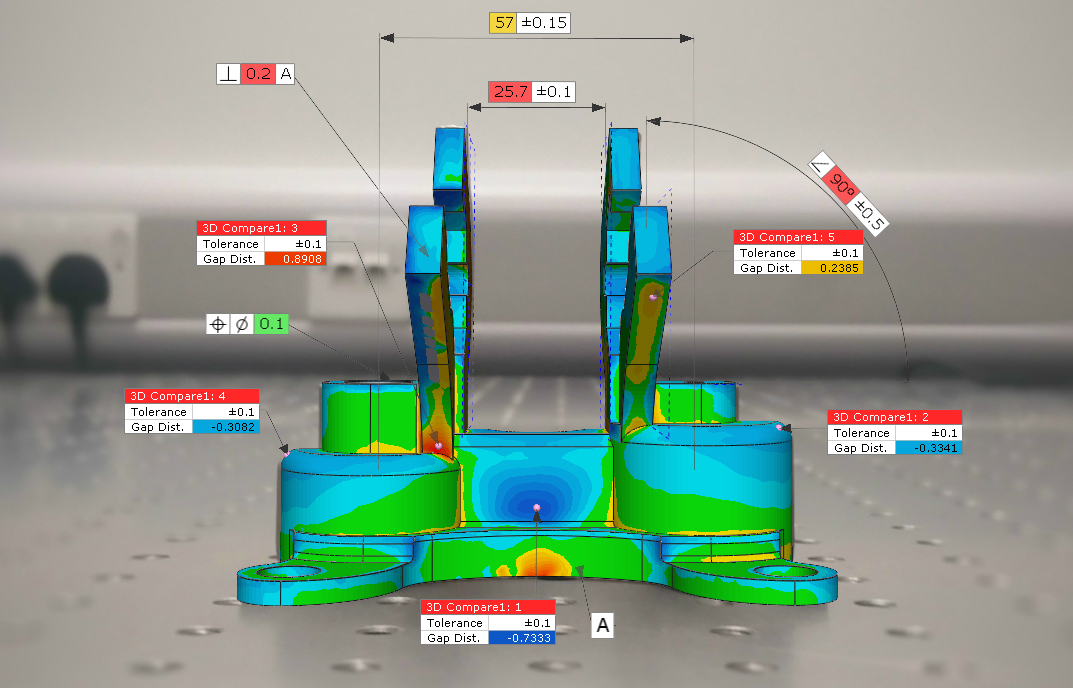

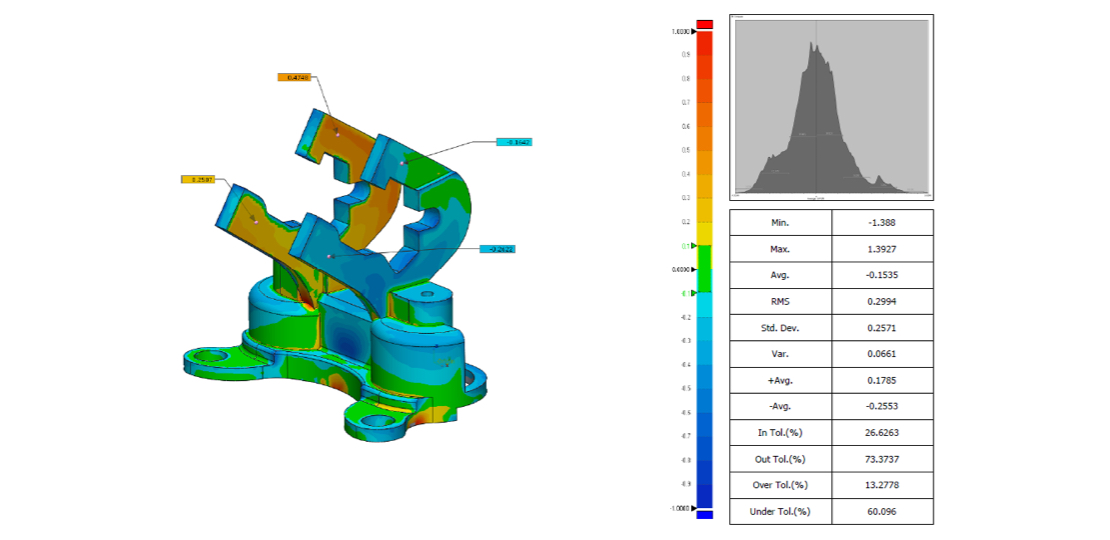

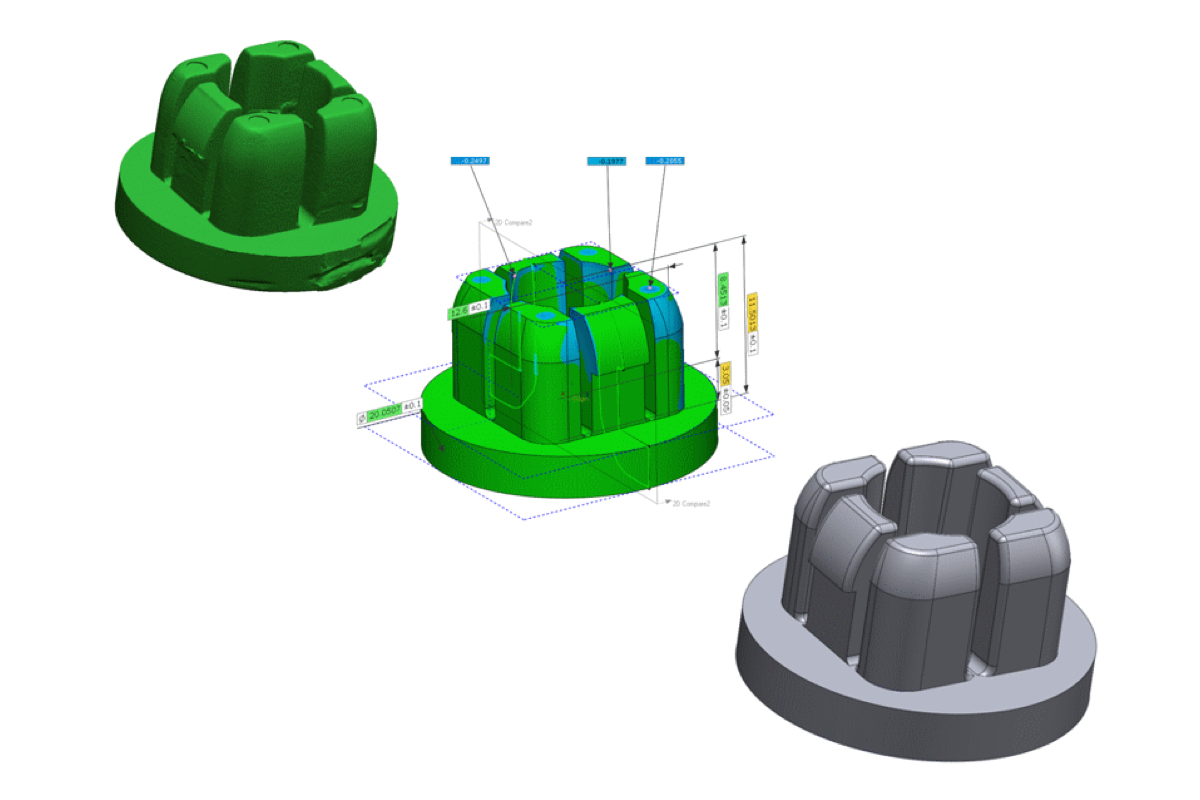

We can also provide you with a 3D Inspection report

We are able to provide 3D inspection reports which are used for quality assurance purposes.

The usual deliverable to the client is in the form of a PDF report, including a 3D page where you can view the deviation in an interactive viewer.

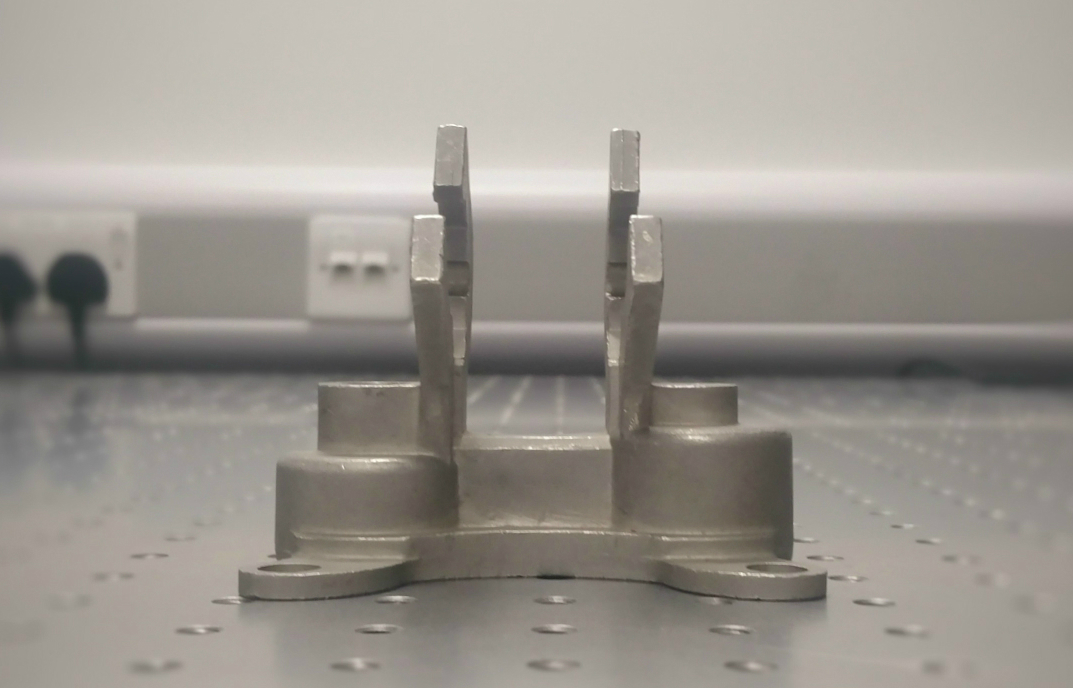

For smaller parts we can use a range of technologies (Laser, Structured Light or CT) providing accuracies suitable for the application. For larger parts that cannot be moved, such a tooling, jigs or large installations, we use portable solutions (Portable CMM, Laser Tracker) to inspect in situ.

The laser tracker is commonly used to inspect geometry of larger components. With accuracies of 5µm/m, it is perfect to check alignment, layout or geometric tolerances of objects ranging in size up to 160m from a single position. For layouts of equipment on a larger scale, the laser tracker can be moved to multiple positions to take measurements where the range needs to be extended or line of sight is obstructed.

Inspection reports may also be created from long range scan data. Deviation is calculated from a CAD nominal or previous base line scan data.

“I first saw OR3D at a MAC event at the NEC, in Birmingham, when James was holding practical demonstrations. I realised how much easier it would be for us to have our products scanned and then rendered to make 3D models as, with clients across the world, sometimes language can be a barrier. We previously used photographs to advertise our products, but these 3D images are consistent, our products look uniform, and the overall effect is informative and professional. I would certainly recommend OR3D and look forward to using their services again.”

Simon Hanmer (Managing Director of Freddy Products)

Did you find this page useful?