DR is useful for finding internal defects fast. Broken wires, misaligned components and more can be identified quickly and easily using DR. If more analytical information is required then often a computed tomography or CT scan is required.

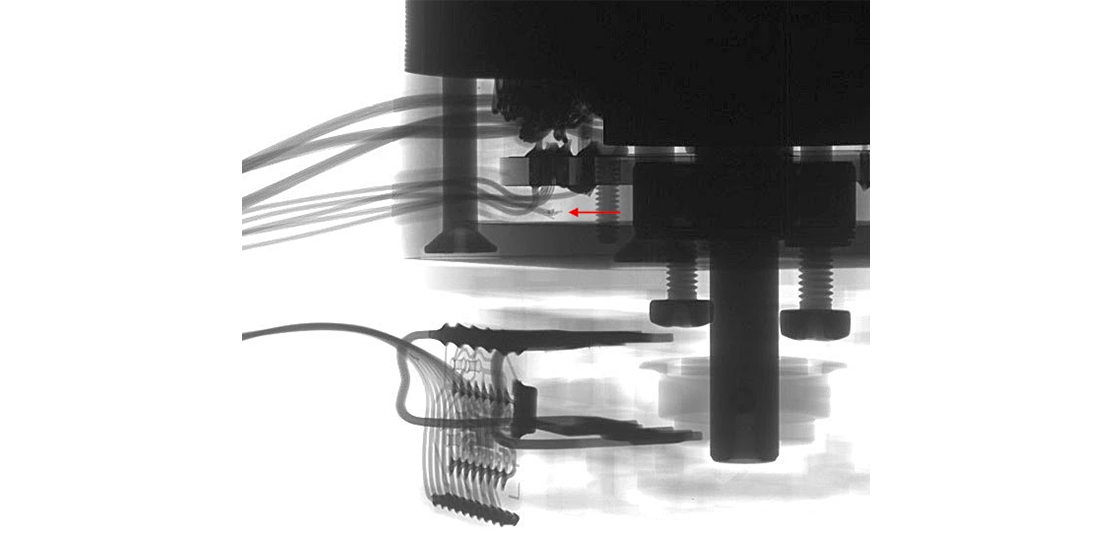

Assessing electrical faults can be difficult, especially when the electrical assembly is hidden inside of another component. Here you can clearly see a broken wire inside the of the part. Go/No Go checks on parts like this can be made quickly with digital radiography.

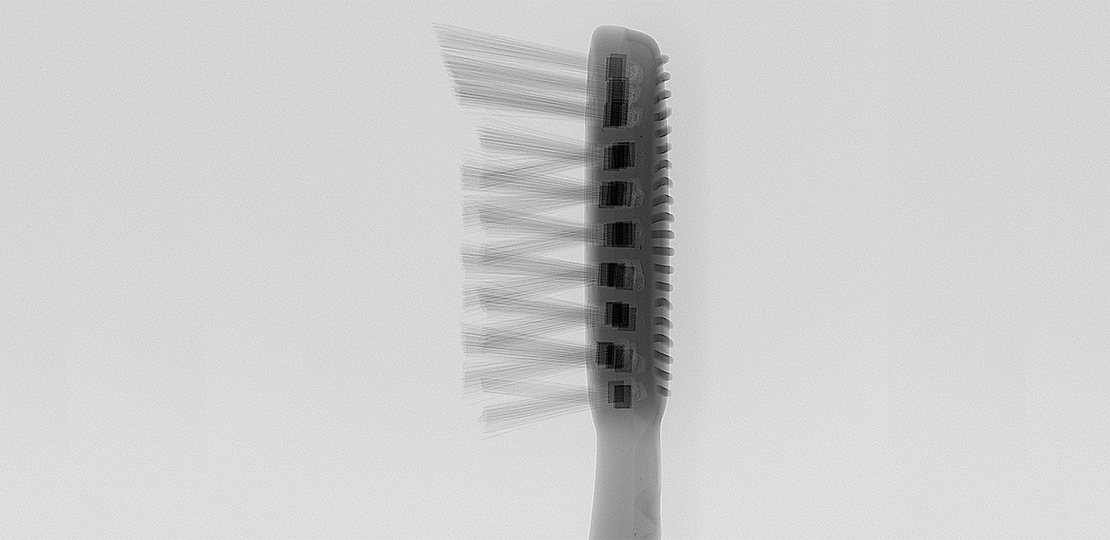

Visualise the assembly of components using digital radiography to asses everything is assembled correctly. This technique can be combined with AI solutions which can automatically spot assembly errors or other defects.

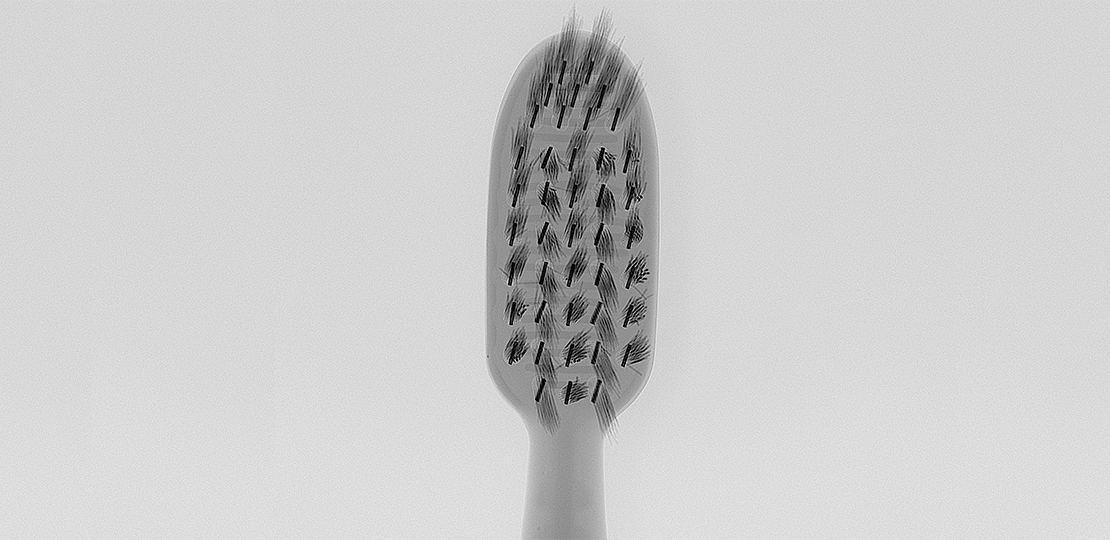

Digital radiography can be used as a quick way of assessing the presence of internal defects such as porosity. In this image we can clearly see the air pockets (pores) in the plastic moulding on this hex key. The lighter areas where the pores are located and due to the presence of less material attenuating the xrays.

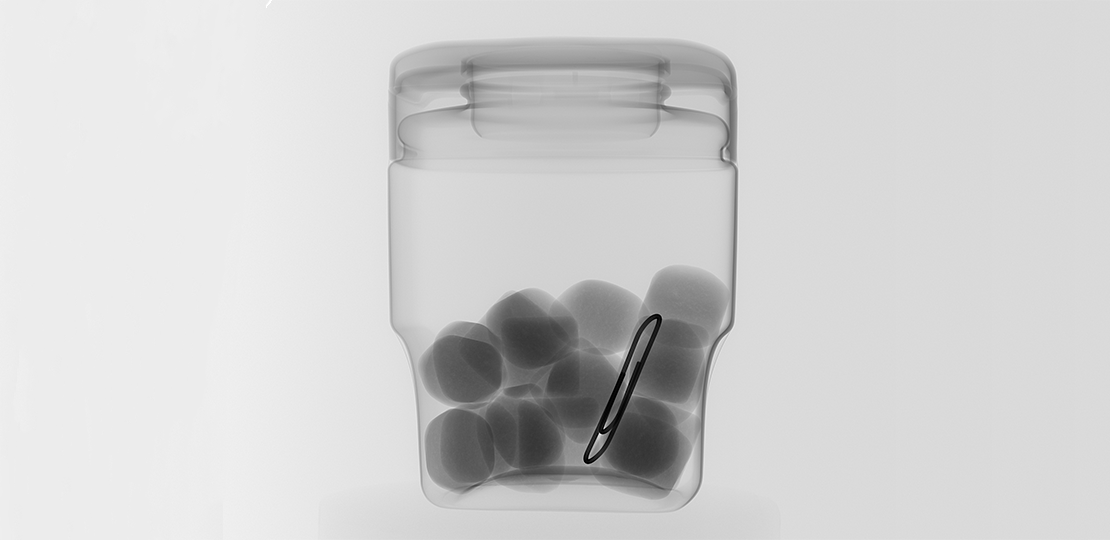

A digital radiograph can be used to clearly show metallic or other dense materials inside packaging even if the contaminant is not magnetic. Here we can clearly identify the paperclip inside the pack of chewing gum.

Speak to us today on

+44 (0) 1691 777 774

3 Cedar Court, Brynkinalt Business Centre, Chirk, Wrexham, LL14 5NS

Find Us